-

-

-

Customer #{{vm.session.billTo.customerNumber}} Sales Rep

{{::vm.session.salesPerson.name}}

{{vm.formatPhone(vm.session.salesPerson.phone1)}} {{vm.formatPhone(vm.session.salesPerson.phone2)}} {{::vm.session.salesPerson.email}} CSR

{{::vm.session.csr.name}}

{{vm.formatPhone(vm.session.csr.phone1)}} {{vm.formatPhone(vm.session.csr.phone2)}} {{::vm.session.csr.email}} Shipping Address

{{::vm.session.shipTo.fullAddress}}

-

-

-

Shop Products

- Back

- Towels Tissue & Wipers

- Hand Soap / Skin Care

-

Cleaning Chemicals

- View All

- Back

- Covid-19 Defense

- Aerosols

- All Purpose Cleaners

- Green Cleaning Chemicals

- Peroxide Cleaners

- Industrial Cleaners Degreasers

- Glass & Window Cleaners

- Restroom Care

- Disinfectants & Sanitizers

- Disinfectant Sanitizing Wipes

- Deodorant & Odor Control

- Dilution Control Chemicals

- Hard Floor Care

- Carpet Floor Care

- Bleach Ammonia & Drain Cleaners

- Bio Augmentation & Enzymes

- Insecticides

- Specialty Cleaners

- Laundry Chemicals & Equipment

- Warewashing Chemicals & Equipment

- Food Sanitation Products

- Pool Chemicals & Supplies

- Production Chemicals

- Misc. Chemicals

- Dispensers & Dilution Control

- Dispensers & Parts

- Can Liners & Garbage Bags

-

Cleaning Tools

- View All

- Back

- Bottles Triggers & Pumps

- Bowl Mops & Plungers

- Brooms Hand Brushes & Dustpans

- Buckets Mop Buckets & Wringers

- Cleaning Carts

- Dust Mops Handles & Tools

- Floor Screens & Hand Pads

- Floor Squeegees & Handles

- Microfiber Mops & Flat Mops

- Misc. Supplies & Tools

- Safety Signs & Tape

- Scrapers & Shovels

- Service Carts & Utility Carts

- Sponges

- Waste Containers

- Wet Mops & Handles

- Window Squeegees & Tools

- Personal Care

-

Janitorial Equipment

- View All

- Back

- Actuators

- Battery Chargers

- Brushes & Pad Drivers

- Electric Motors

- Engine Parts

- Filters

- Floor Pads

- Gaskets

- Hardware

- Hoses

- Hydraulic Motors

- Solution Pumps & Valves

- Squeegees

- Vacuum Motors

- Wheels, Tires & Castors

- Back Pack Hip Vacuums

- Vacuums & Sweepers

- Wet Dry Vacuums

- Wind Blowers

- Pressure Washers & Sprayers

- Swing Floor Machines

- Extractors

- Burnishers

- Automatic Floor Scrubbers

- Misc. & Specialty Equipment

- Warewash Equipment

- Vacuum Bags

- Rental Equipment

- Janitorial Parts

- Industrial Supplies

-

Shipping Supplies

- View All

- Back

- Packing Envelopes & Labels

- Paper Pallet & Tubing

- Carton Sealing Tape & Dispensers

- Filament Tape & Dispensers

- Stretch Film

- Banding Strapping & Tools

- Cushion & Padded Mailers

- Corrugated Boxes

- Stitching Wire & Staples

- Labels Tags & Marking Supplies

- Carton Sealing Adhesive

- Misc. Shipping Supplies

-

Packaging Supplies

- View All

- Back

- PE Foam

- Edge & Corner Protection

- Corrugated Rolls & Pads

- Bubble Wrap & Bags

- Kraft Paper Butcher Paper Newsprint & Chipboard

- Plastic Bags Sheeting & Tubing

- Void Fill

- Polymask & Surface Protection

- Shrink Film & Bags

- Furniture Wadding & Sleeves

- Instapak & Supplies

- Honeycomb

- Misc. Packaging Materials

- Packaging Equipment

- Safety

- Facility Supplies

- Office Supplies

- Food Service Disposables

- Closeout Specials

- Programs

- Markets Served

- Training & Events

- About Us

Attention

Your session will be automatically logged out after another {{vm.remainingTimeToLoggedOut}} minutes of inactivity.

Attention

Your session has been logged out.

-

Shop Products

- Towels Tissue & Wipers

- Hand Soap / Skin Care

-

Cleaning Chemicals

- View All

- Covid-19 Defense

- Aerosols

- All Purpose Cleaners

- Green Cleaning Chemicals

- Peroxide Cleaners

- Industrial Cleaners Degreasers

- Glass & Window Cleaners

- Restroom Care

- Disinfectants & Sanitizers

- Disinfectant Sanitizing Wipes

- Deodorant & Odor Control

- Dilution Control Chemicals

- Hard Floor Care

- Carpet Floor Care

- Bleach Ammonia & Drain Cleaners

- Bio Augmentation & Enzymes

- Insecticides

- Specialty Cleaners

- Laundry Chemicals & Equipment

- Warewashing Chemicals & Equipment

- Food Sanitation Products

- Pool Chemicals & Supplies

- Production Chemicals

- Misc. Chemicals

- Dispensers & Dilution Control

- Dispensers & Parts

- Can Liners & Garbage Bags

-

Cleaning Tools

- View All

- Bottles Triggers & Pumps

- Bowl Mops & Plungers

- Brooms Hand Brushes & Dustpans

- Buckets Mop Buckets & Wringers

- Cleaning Carts

- Dust Mops Handles & Tools

- Floor Screens & Hand Pads

- Floor Squeegees & Handles

- Microfiber Mops & Flat Mops

- Misc. Supplies & Tools

- Safety Signs & Tape

- Scrapers & Shovels

- Service Carts & Utility Carts

- Sponges

- Waste Containers

- Wet Mops & Handles

- Window Squeegees & Tools

- Personal Care

-

Janitorial Equipment

- View All

- Actuators

- Battery Chargers

- Brushes & Pad Drivers

- Electric Motors

- Engine Parts

- Filters

- Floor Pads

- Gaskets

- Hardware

- Hoses

- Hydraulic Motors

- Solution Pumps & Valves

- Squeegees

- Vacuum Motors

- Wheels, Tires & Castors

- Back Pack Hip Vacuums

- Vacuums & Sweepers

- Wet Dry Vacuums

- Wind Blowers

- Pressure Washers & Sprayers

- Swing Floor Machines

- Extractors

- Burnishers

- Automatic Floor Scrubbers

- Misc. & Specialty Equipment

- Warewash Equipment

- Vacuum Bags

- Rental Equipment

- Janitorial Parts

- Industrial Supplies

-

Shipping Supplies

- View All

- Packing Envelopes & Labels

- Paper Pallet & Tubing

- Carton Sealing Tape & Dispensers

- Filament Tape & Dispensers

- Stretch Film

- Banding Strapping & Tools

- Cushion & Padded Mailers

- Corrugated Boxes

- Stitching Wire & Staples

- Labels Tags & Marking Supplies

- Carton Sealing Adhesive

- Misc. Shipping Supplies

-

Packaging Supplies

- View All

- PE Foam

- Edge & Corner Protection

- Corrugated Rolls & Pads

- Bubble Wrap & Bags

- Kraft Paper Butcher Paper Newsprint & Chipboard

- Plastic Bags Sheeting & Tubing

- Void Fill

- Polymask & Surface Protection

- Shrink Film & Bags

- Furniture Wadding & Sleeves

- Instapak & Supplies

- Honeycomb

- Misc. Packaging Materials

- Packaging Equipment

- Safety

- Facility Supplies

- Office Supplies

- Food Service Disposables

- Closeout Specials

- Programs

- Markets Served

- Training & Events

- About Us

Don't get caught with a recall...

We’ve all seen it…the dreaded recall! No matter the industry, no one wants to hear those words, but especially not when it comes to our food. I’m sure you can think back to a time you just bought your groceries, only to find out something has been recalled. That is why food safety is important, especially in Food Processing to make sure recalls are avoid.

We’ve all seen it…the dreaded recall! No matter the industry, no one wants to hear those words, but especially not when it comes to our food. I’m sure you can think back to a time you just bought your groceries, only to find out something has been recalled. That is why food safety is important, especially in Food Processing to make sure recalls are avoid.

September is Food Safety Month. There are many factors that food processing businesses need to consider when it comes to food safety. Following the necessary food safety standards and regulations can help prevent outbreaks of the dreaded food-borne illnesses: Salmonella, E. coli and Campylobacter.

I broke it down to some of the critical areas of focus that will help you to ensure that food safety is applied in your business.

1. Facilities Design and Maintenance: The layout of the production line should allow easy maintenance and cleaning of machinery and surroundings to prevent contamination of the food products and ingredients during the production process.

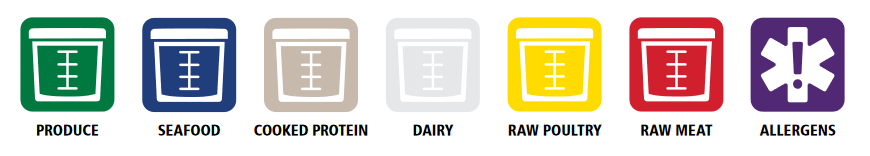

2. Waste Management: Provide appropriate containers and suitable waste storage areas. A great first step in implementing a waste management system is establishing a color coded waste container system. This prevents build-up of waste and reduces risk of contamination of ingredients, equipment and products. New to the color-coding in food production? No worries, here are some suggestions:

3. Cleaning: Work with your Nichols Sales Representative to establish cleaning and disinfection programs to ensure the correct hygiene standards are met and reduce the risk of a foodborne illness outbreak. This includes properly cleaning and disinfecting food preparation areas, the machines and any utensils used within the food processing cycle. A proper cleaning program will eliminate the microorganisms that cause food poisoning and recalls.

4. Personal Hygiene: Installing the correct systems for staff to ensure proper personal hygiene is met contributes towards meeting food safety requirements. Bacteria can easily be spread through biological and physical contamination, putting foods at high risk of carrying food-borne diseases. You can easily add hand sanitizer stations throughout your facility and hands free soap dispensers in your restrooms.

5. Environmental Hygiene: Food safety practices need to be applied to ensure the chemicals stored and used on food processing premises do not contaminate the product at any stage in production. Nichols works with several manufacturers that have dispensing systems and wall mounts to make storage safer and cleaner.

6. Correct Handling, Storage & Transport: A range of factors need to be considered during the handling, storage and transportation stages to ensure food products do not become contaminated. Temperature and humidity, hygiene of vehicles, containers and packaging are all factors which need considering during these stages of the food supply chain.

7. Staff Training: Educating staff on how to ensure food safety practices are followed will help reduce the risk of contamination. Regulations require that food handlers are supervised and trained in food hygiene practices suitable for their work activity. Your staff should be trained in hand hygiene, safe food storage practices, safe food handling practices and cleaning for food safety. Did you know Nichols provides training and seminar workshops on many topics like food safety and hand hygiene? All at no extra cost to our customers, just an added value for being a customer.

You don’t want to wait until it is too late! Don’t get caught in a food recall, contact your local Nichols Sales Representative for cleaning chemical and waste management information, or to schedule a training.